- Unit -112 & 113 30553 Great Northern Ave, Abbotsford, BC V4X 2N2

- (778) 970 -0739

- contact@multiaxis.ca

IF A JOB IS WORTH DOING, IT’S WORTH PERFECTING.

We are your partner from design to production and beyond.

Precision Sheet Metal Fabrication & Machined Component Manufacturer That You Can Trust

Discover the power of precision and innovation at MultiAxis Manufacturing.

As a specialized sheet metal fabrication company, we combine state-of-the-art equipment, skilled personnel, and industry-leading software to deliver custom, high-quality sheet metal products that exceed expectations.

Unmatched Material Expertise

We excel in working with various materials, including:

Cold Rolled Steel

Offering strength and durability for versatile applications.

Aluminum

Providing lightweight solutions without compromising on strength.

Satin Coat Steel (Zinc-Iron Alloy)

Delivering corrosion resistance and extended longevity.

Galvanized Steel

Ensuring excellent rust protection and prolonged durability.

Stainless Steel

Known for its strength, corrosion resistance, and aesthetic appeal.

Copper

Offering exceptional electrical conductivity and a distinctive look.

Brass

Combining durability, aesthetic appeal, and corrosion resistance.

Services we provide

Engineering and prototype

Our design team can provide prototype development, as well as complete CAD models and/or drawings for precision custom sheet metal fabricating and prototypes. We accept design files in various formats, including PDF, DXF, DWG, STEP, and SolidWorks.

Prototyping and Customization:

We understand the importance of bringing your ideas to life. Our team is equipped to work closely with you in the prototyping phase, ensuring that your custom designs are accurately translated into functional metal products. Whether you provide your designs or collaborate with us, we support a variety of file formats to streamline the process and ensure precision at every step.

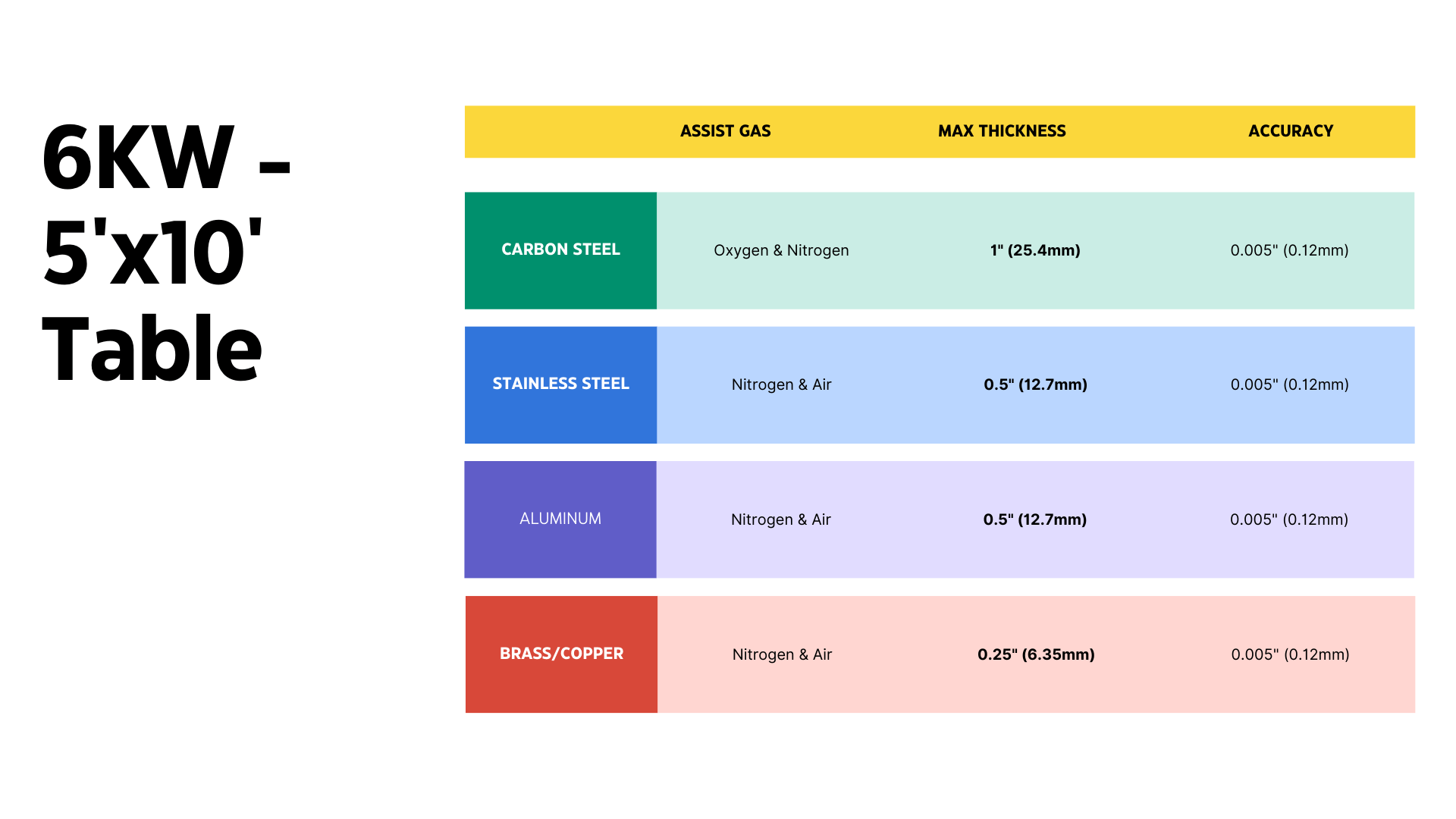

LASER CUTTING

Utilizing our state-of-the-art 6KW Fiber laser cutting technology, we deliver highly precise and intricate cuts across a wide range of metals. This advanced system ensures superior edge quality, tight tolerances, and optimal material utilization, minimizing waste while maximizing efficiency.

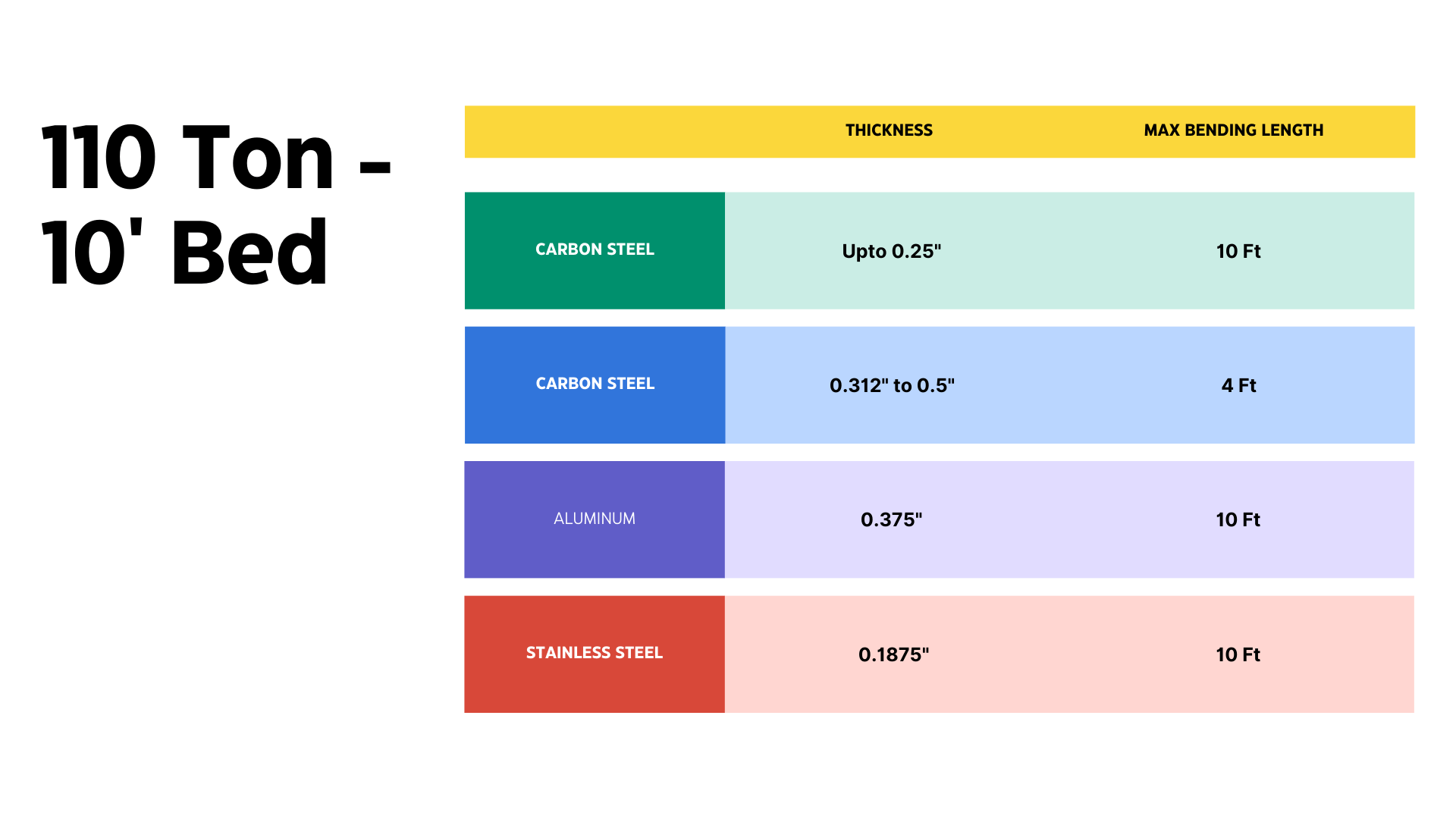

FORMING

Our highly skilled technicians leverage precision press brakes, rolling machines, and advanced forming equipment to shape metal sheets into complex configurations. With the capability to produce precise bends, curves, angles, and rolls, we ensure that your design specifications are met with the highest level of accuracy and quality.

Welding and Assembly

At MultiAxis, we offer expert welding services, ensuring the seamless joining of metal components with precision and strength. Our highly skilled welders specialize in a range of welding techniques, including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and spot welding, to deliver reliable, durable welds that adhere to the highest industry standards. In addition to welding, we provide comprehensive assembly services to streamline your production process and deliver fully assembled components. We also offer PEM inserting for fastening solutions, ensuring secure and efficient integration of hardware into your metal assemblies. Whether your project involves structural welding, custom fabrication, assembly, or repairs, we have the expertise to handle jobs of all sizes with unmatched quality and efficiency.

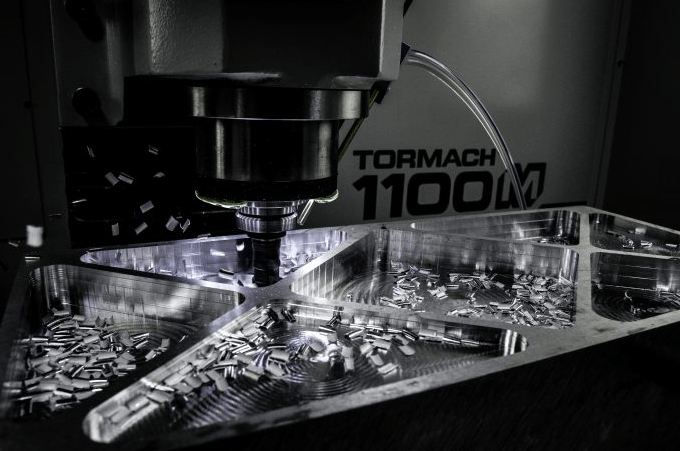

CNC Machining as a Complementary Operation

At MultiAxis, we offer advanced CNC (Computer Numerical Control) machining as a complementary operation to enhance our sheet metal fabrication services. Our CNC machines allow us to precisely shape and cut components from a variety of materials, including metals and plastics. While our primary focus is sheet metal fabrication, our CNC milling, turning, drilling, and grinding capabilities provide the flexibility to refine and complete your custom metal projects with exceptional accuracy and efficiency. This ensures we can meet intricate design specifications and accommodate a wide range of machining needs.

Powder Coating

At MultiAxis, we specialize in powder coating to enhance the durability and appearance of your metal products. This finishing process provides a tough, long-lasting protective layer that is resistant to corrosion, scratches, and fading. With a wide variety of colors and textures available, our powder coating services ensure your products achieve both a professional look and superior protection for demanding environments.

Quality Assurance

At MultiAxis, our commitment to excellence is reflected in our rigorous quality assurance processes. We adhere to industry-leading standards, ensuring that every product meets the highest levels of precision and reliability. Our quality control includes First Article Inspection (FAI), detailed in-process inspections, Final Inspection Reports (FIR), and final product audits to ensure compliance with your exact specifications. Each phase of production is closely monitored by our skilled craftsmen and quality control team to guarantee that you receive flawless, high-quality products, delivered on time and to your satisfaction.